and heavy lifting for bridge construction.

and heavy lifting for bridge construction.

PT SYSTEMS

Extensively tested and performance-proven on major civil engineering projects worldwide

Hoover Dam Bypass

Boulder City, Nevada

SDI’s Multistrand Systems suit traditional and progressive structural designs —including lightweight, high-strength concrete mixes and compact anchors in challengingly congested reinforced steel. Extensive testing and decades of sound performance worldwide demonstrate superior systems and innovative solutions for an array of applications: precast and cast-in-place segmental bridges, nuclear containment, wind towers, tanks, and offshore oil drilling.

SDI furnishes comprehensive material supply and installation services for post-tensioning projects worldwide. The system hardware incorporates numerous technical advances that simplify field placement, stressing, and grouting and includes a broad range of encapsulation features for ultimate corrosion protection.

stay cable systems

Design and supply of temporary and permanent stay cable systems

SDI offers a full range of stay cables for permanent and temporary applications including shop-fabricated Bridge Cables and Lock Coil Cables as well as field-fabricated stay cables using prestressing strand. SDI stay cables and anchorages have been tested to strict industry standards and are approved for use in a wide range of applications.

TILIKUM CROSSING

Portland, Oregon

Application Examples

Temporary Support

Hoover Dam Bypass Bridge, Tilikum Crossing, Crooked River Bridge

Permanent stay cables

Pearl Harbor Memorial Bridge in New Haven, Connecticut: the first extradosed bridge in the United States

Mary Avenue Bridge / Sundial Bridge / Beltline Bridge

Service Range

Material Supply, Lease of installation and tensioning equipment, Technical assistance, Full installation services

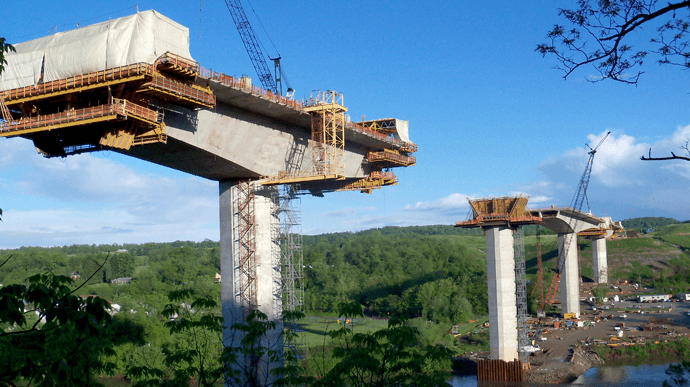

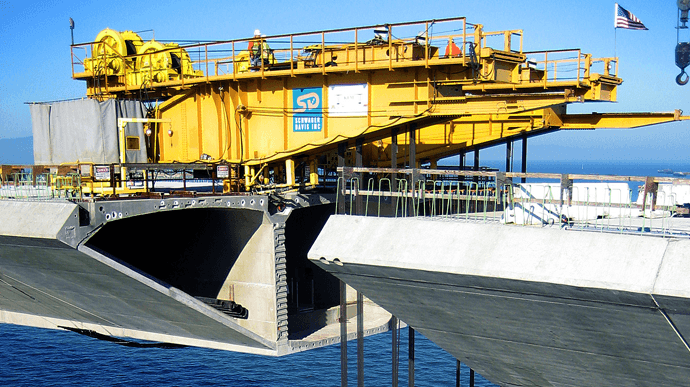

HEAVY LIFTING

One-stop Source for Engineered Lifts and Rigging

Schuyler Heim Bridge

Long Beach, California

Schwager Davis, Inc. excels at finding effective solutions to heavy lifting challenges.

With safety and practicality always top priority, we engineer solutions that deliver projects on time and within budget. Our principals’ Engineering News-Record (ENR) Top Newsmaker awards and constantly increasing track record of success on major civil engineering projects underscore SDI’s commitment to responsive client service and engineering excellence.

Whether lifting 800 Ton bridge segments or lowering massive loads for demolition, SDI has the experienced engineering staff and equipment required for your heavy lift needs.

Schuyler Heim Bridge

Long Beach, California

Schwager Davis, Inc. excels at finding effective solutions to heavy lifting challenges.

With safety and practicality always top priority, we engineer solutions that deliver projects on time and within budget. Our principals’ Engineering News-Record (ENR) Top Newsmaker awards and constantly increasing track record of success on major civil engineering projects underscore SDI’s commitment to responsive client service and engineering excellence.

Whether lifting 800 Ton bridge segments or lowering massive loads for demolition, SDI has the experienced engineering staff and equipment required for your heavy lift needs.

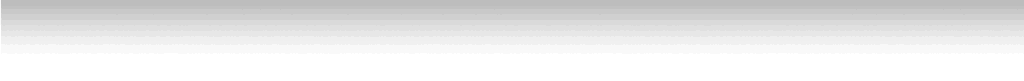

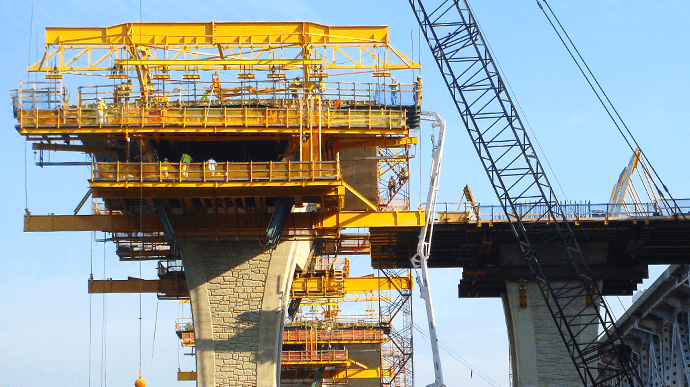

bridge erection equipment

Maximizing constructibility through innovative design

Decades of successful bridge construction have earned SDI the requisite competence and confidence to develop numerous bridge

building methods.

Our practical construction solutions, combined with innovative new designs for our form travelers, segment lifters, stay cables, and heavy lifting equipment optimize a project’s schedule, economy, and labor efficiency.

With nearly 20 projects on our resume utilizing the cast-in-place erection method, SDI offers invaluable experience and know-how required for a safe and successful conclusion.

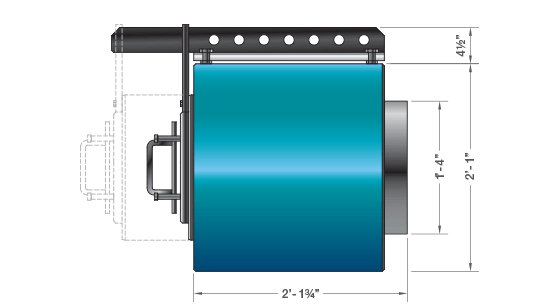

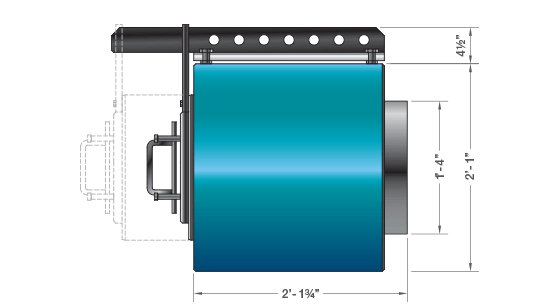

SDI offers Form Travelers for lease or sale with the option to include formwork.

Our travelers are modular; they can adapt to various cross sections and varying roadway alignments. As all connections are pinned, it allows for quick and easy assembly and removal. SDI provides full engineering calculations and certification that the travelers will meet project requirements and provides traveler loading and deflection calculations for use in the contractor’s geometry control plan.

energy infrastructure

Engineering and construction services for owners and contractors wordwide

Golden Pass LNG

Sabine Pass, Texas

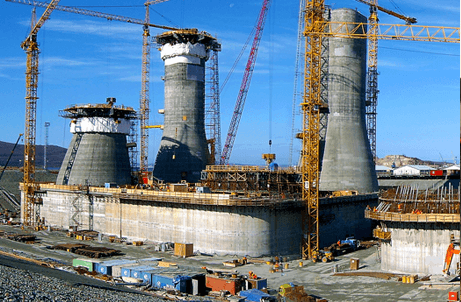

Containment Post Tensioning System

SDI’s core management team has been active in the nuclear construction markets since the mid-1970s. We have an established, US-Industry approved, 10CFR50 Appendix B Quality Assurance Program in place to support the following services:

- Design, furnish, and install the Containment PT System (CPTS) tendons and hardware for current and next-generation nuclear power plants

- Repair or replace existing CPTS tendons and hardware

- Tendon surveillance programs for existing multi-strand and button-head CPTS applications

- Design and fabrication services for specialized equipment required for CPTS access, installation, and maintenance

- Procurement services available for supply of CPTS tendon and hardware as Dedicated Safety-Related Components

LNG Storage Tanks & Other Large Capacity Tanks

SDI has extensive experience with construction of large capacity post-tensioned tank structures, including Liquid Natural Gas (LNG) Storage Tanks, AWWA D115 Tendon Prestressed Concrete Tanks, and digester tanks. With the largest furnish and install contract in the United States completed at the Golden Pass LNG Terminal, SDI is well-suited fort his type of construction.

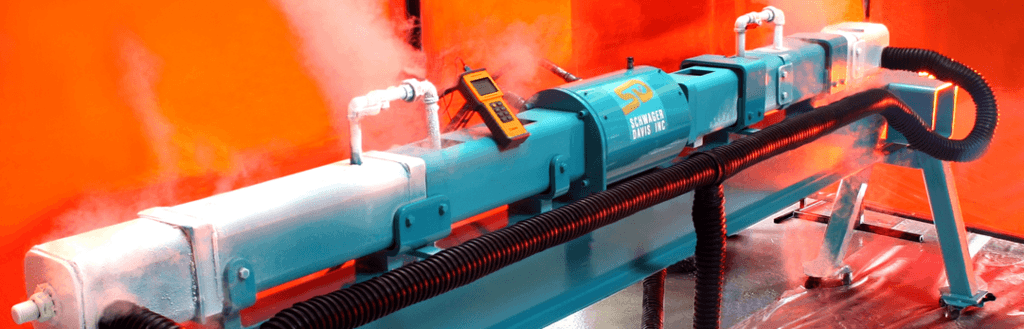

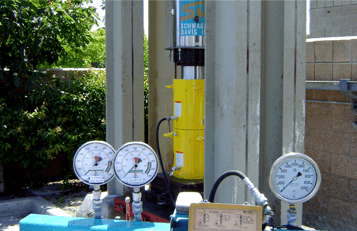

The SDI post-tensioning system has been successfully tested at cryogenic temperatures for use in LNG storage facilities. SDI maintains a large inventory of specialized post-tensioning installation equipment and also offers installation access platforms for lease or sale.

Wind Towers

SDI was instrumental in the successful installation of the tallest wind tower in North America. At 377 feet to the hub it makes it 44% taller than anything in the United States.

With blades at full height, the turbine reaches an astonishing 554 feet. Towers used to support wind turbines are conventionally constructed from steel but due to transportation restraints, the height, and in turn, the potential to capture more wind, is limited. With post-tensioned concrete towers cast on site, the sky is now the limit.

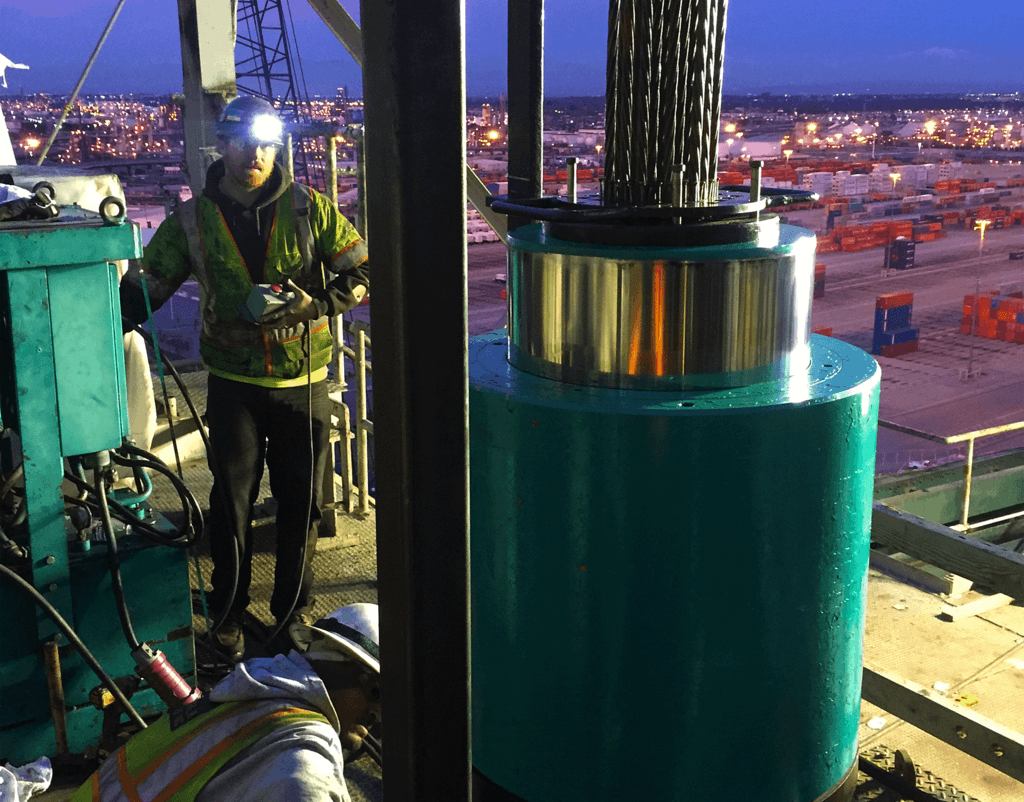

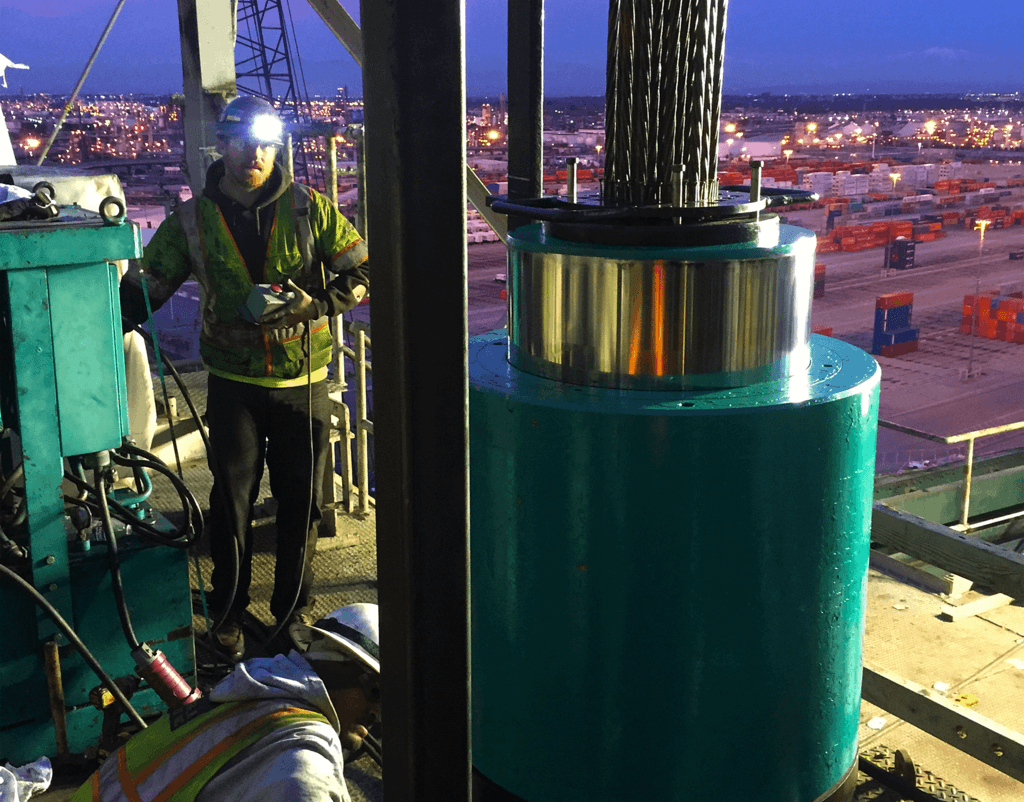

Gravity Based Structures (GBS)

For the support of oil and gas production facilities.

Over the past 30 years, SDI staff has managed the post-tensioning activities of more than 75% of all GBS structures worldwide. Services include:

- Post-tensioning design

- Furnishing of post-tensioning materials

- Labor and supervision for post-tensioning installation

- Specialty equipment and testing services

Containment Post Tensioning System

SDI’s core management team has been active in the nuclear construction markets since the mid-1970s. We have an established, US-Industry approved, 10CFR50 Appendix B Quality Assurance Program in place to support the following services:

- Design, furnish, and install the Containment PT System (CPTS) tendons and hardware for current and next-generation nuclear power plants

- Repair or replace existing CPTS tendons and hardware

- Tendon surveillance programs for existing multi-strand and button-head CPTS applications

- Design and fabrication services for specialized equipment required for CPTS access, installation, and maintenance

- Procurement services available for supply of CPTS tendon and hardware as Dedicated Safety-Related Components

LNG Storage Tanks & Other Large Capacity Tanks

SDI has extensive experience with construction of large capacity post-tensioned tank structures, including Liquid Natural Gas (LNG) Storage Tanks. With the largest furnish and install contract in the United States completed at the Golden Pass LNG Terminal, SDI is well-suited fort his type of construction.

The SDI post-tensioning system has been successfully tested at cryogenic temperatures for use in LNG storage facilities. SDI maintains a large inventory of specialized post-tensioning installation equipment and also offers installation access platforms for lease or sale.

Wind Towers

SDI was instrumental in the successful installation of the tallest wind tower in North America. At 377 feet to the hub it makes it 44% taller than anything in the United States.

With blades at full height, the turbine reaches an astonishing 554 feet. Towers used to support wind turbines are conventionally constructed from steel but due to transportation restraints, the height, and in turn, the potential to capture more wind, is limited. With post-tensioned concrete towers cast on site, the sky is now the limit.

Gravity Based Structures (GBS)

For the support of oil and gas production facilities.

Over the past 30 years, SDI staff has managed the post-tensioning activities of more than 75% of all GBS structures worldwide. Services include:

- Post-tensioning design

- Furnishing of post-tensioning materials

- Labor and supervision for post-tensioning installation

- Specialty equipment and testing services

Post-tensioning repair

A leader in the repair and alteration of post-tensioned concrete and steel structures